Zero Liquid Discharge

We offer our clients Zero Liquid Discharge Systems designed on advanced user friendly technologies.

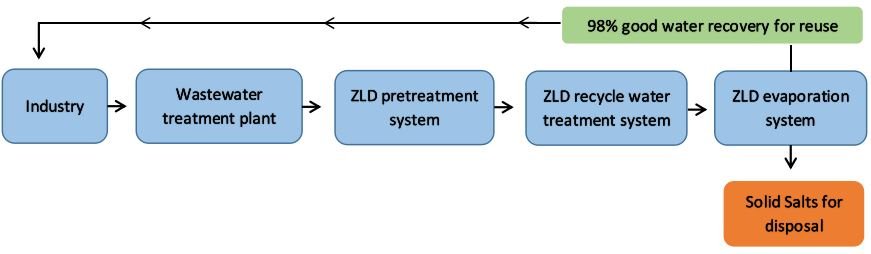

ZLD is a water treatment process in which wastewater is treated, purified and further recycled. The ZLD process completely eliminates liquid discharge from industry thus reduces & eliminates possibility of pollution discharge concerns & regulatory disposal norms.

A well-designed Zero Liquid Discharge System (ZLD System) is used to minimize the volume of liquid waste that requires treatment, while also producing a clean stream suitable for use elsewhere in the plant processes.

A common ZLD approach is to concentrate the wastewater through well designed multiple membrane systems and then dispose of it as a liquid brine or further crystallize the brine to a solid. A typical evaporator (MEE) uses tube-style heat exchangers. The evaporated water is recovered and recycled while the brine is concentrated to a higher solids concentration. Concentrated brine treatment is done in a crystallizing system, such as Agitated Thin Film Dryer (ATFD) or a spray dryer. Crystallized solids in most of the cases is categorised as hazardous waste and disposed off periodically. We offer our clients Zero Liquid Discharge Systems designed on advanced user friendly technologies.

ZLD System benefits:

- Elimination of pollution discharge concerns

- Elimination of regulatory disposal norms

- Almost 98% good water recovery

- Self sustainable water usage industry

- Meets social responsibility

- Reduction of dependence on water supply source agency

ZLD Supplier with an extra edge:

Apex Ecotech is known as well recognised and of the best ZLD (zero liquid discharge) Supplier. We offer zero liquid discharge (ZLD) plant with advanced ZLD treatment process with minimal operations & delivers best ZLD performance. Our past rich ZLD projects expertise has rated us one of the best ZLD supplier in India. Our system integration have an extra edge while comparing with rest of the best available ZLD suppliers.

ZLD Pretreatment Stage:

ZLD Pretreatment Stage is one of the most important treatment stage. We offer reliable ZLD pretreatment system includes Electro Chemical Treatment, Lime Soda Ash Softening, Advanced Biological treatment like MBR (Membrane Bio Reactor).

ZLD recycle water stage:

Multistage RO Membrane System is commonly used in ZLD recycle system for recovering low TDS (less saline) water from high TDS (high saline) water. However, RO Membrane System is prone to frequent fouling and requires highly stringent feed water conditioning.

We also offer advanced treatment technology EDR (Electro Dialysis Reversal) in place of Multistage RO and consistently can achieve 90% or more water recovery, EDR ensures high water recovery & lesser waste water generation. The EDR capex paybacks is achieved at times in less than 02 years.

ZLD Evaporation Stage:

Final concentrated reject water generated from Multistage RO or EDR is evaporated by suitable thermal or non-thermal treatment process. Most common evaporator used is MEE (Multi-effect Evaporator) followed by Salt Crystalliser, Agitated Thin Film Dryer (ATFD) or Pusher Centrifuge System.

For lower operating expenses, MVR technology (Mechanical Vapor Recompression) is most suitably used. MVR technology adoption is ideal for cases with higher waste water volumes to be handled through ZLD process.

For intensive solar radiation available locations MD (Membrane Distillation) evaporation technology can be offered with minimal running cost.

Evaporation Technologies involved in ZLD

1. HYBRID FALLING FILM & FORCED CIRCULATION EVAPORATORS (MULTI EFFECT EVAPORATOR - MEE)

a) Cost effective solution towards low salinity rejects having a feed salinity between 5 to 10%.

b) Best steam economy.

c) Low power costs due to first stages of falling film evaporation.

d) Flexibility in selection of material of construction.

e) Combination of pre-heaters and thermo vapor compressor ensures further steam economy.

2. FORCED FILM EVAPORATORS (MULTI EFFECT EVAPORATOR - MEE)

a) Cost effective solution towards high salinity rejects.

b) Reverse feed arrangement ensures maximum utility of motive steam.

c) Horizontal configuration reduces space and height requirement and provides ease of monitoring and maintenance.

d) All monitor- able parameters can be visualized at one level apart from virtual visualization on the HMI/ SCADA screen.

3. ATFD (AGITATED THIN FILM DRYER) CRYSTALLISERS (MEE)

a) Crystallizes the final slurry to salt containing less than 10% moisture.

b) Adjustable blade arrangement ensures flexibility to varying input quality of crystallizable salts.

c) Minimal maintenance and extremely compact design saves on space requirements.

d) Placed on the same platform as that of evaporator flash vessels and hence can be easily monitored at one level apart from virtual visualization on the HMI/ SCADA screen.